Features

STRUCTURE

Flying-optics

Flying-optics

Extremely rigid aluminum gantry structure and high precision rack and pinion

Extremely rigid aluminum gantry structure and high precision rack and pinion

PROTECTION

Broad view, easy for operating and testing. Bellows protecting for the beam path, pressurized ultra-clean gas inside to prevent the dust and longer the mirrors lifetime.

Broad view, easy for operating and testing. Bellows protecting for the beam path, pressurized ultra-clean gas inside to prevent the dust and longer the mirrors lifetime.

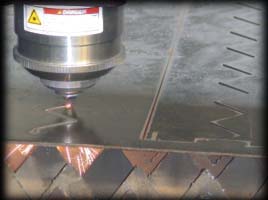

CUTTING HEAD

Originally imported from USA/EU. Digital readout focus position

Originally imported from USA/EU. Digital readout focus position

"No tools" quick lens change and inspection

"No tools" quick lens change and inspection

Collision protection

Collision protection

Capacitive sensor, auto positioning of the sheet

Capacitive sensor, auto positioning of the sheet

Operating Svstem

Smart Manager is originally imported from Europe which has been popular used This software is based on the Windows XP system and can fully interface with Italy CNC system which original imported also. Therefore the real control of the machine,the laser source and software update is more convenient and fast.

Smart Manager is originally imported from Europe which has been popular used This software is based on the Windows XP system and can fully interface with Italy CNC system which original imported also. Therefore the real control of the machine,the laser source and software update is more convenient and fast.

Friendly interface, easy to learn and operation; easy to edit the nu merical control program and high readability

Friendly interface, easy to learn and operation; easy to edit the nu merical control program and high readability

Cutting parameters database is available, at the same time the real time adjustment to the cutting parameters in the procedure of cutting to receive the excellent cutting quality

Cutting parameters database is available, at the same time the real time adjustment to the cutting parameters in the procedure of cutting to receive the excellent cutting quality

Optimize various drilling mode, like continuous drilling, pulse drilling, blasting drilling etc.

Optimize various drilling mode, like continuous drilling, pulse drilling, blasting drilling etc.

Optim ize various fast moving mode, have the function of " frog jump and turn off the assisting gas automatically when fast moving. Easier and faster in automatic edge-finding fijnction

Optim ize various fast moving mode, have the function of " frog jump and turn off the assisting gas automatically when fast moving. Easier and faster in automatic edge-finding fijnction

Cutting head automatic calibration function and the response time of Z axis is intensively increased

Cutting head automatic calibration function and the response time of Z axis is intensively increased

WORK TABLE

Six subarea dust suction to ensure the dean cutting environment

Six subarea dust suction to ensure the dean cutting environment

Two working pallets system, convenient to load and unload the material

Two working pallets system, convenient to load and unload the material

CNC Control

New Z32 real time CNC system with dynamic and geometric JERK control

New Z32 real time CNC system with dynamic and geometric JERK control

The date exchange between CNC system and machine drive system is adopted with fiber

The date exchange between CNC system and machine drive system is adopted with fiber

17"TFT with touch screen

17"TFT with touch screen

Remote assistance

Remote assistance

Power modulation for the ultimate cutting quality in the corners z axis following

Power modulation for the ultimate cutting quality in the corners z axis following

Automatically choosing gas type and pressure(N2, 02, Air)

Automatically choosing gas type and pressure(N2, 02, Air)

Auto restart procedure

Auto restart procedure

WORK TABLE

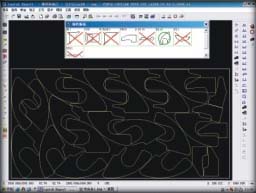

Based on AUTO С AD /САМ automatic program nesting software and easy to use

Based on AUTO С AD /САМ automatic program nesting software and easy to use

Multilayer nesting function to intensively increase the sheet usage rate

Multilayer nesting function to intensively increase the sheet usage rate

Use divisional cutting path to avoid over heat

Use divisional cutting path to avoid over heat

Parameter setting: automatically apply different cutting parameters to different materials and thickness based on customer's requirement

Parameter setting: automatically apply different cutting parameters to different materials and thickness based on customer's requirement

Edge-sharing cutting function optimizes the cutting efficiency and increase the sheet usage rate

Edge-sharing cutting function optimizes the cutting efficiency and increase the sheet usage rate

Pre-perforation: Accomplish the pre-perforation as settled. Make use ofthe rest materials. Second position system suitable for large area cutting

Pre-perforation: Accomplish the pre-perforation as settled. Make use ofthe rest materials. Second position system suitable for large area cutting